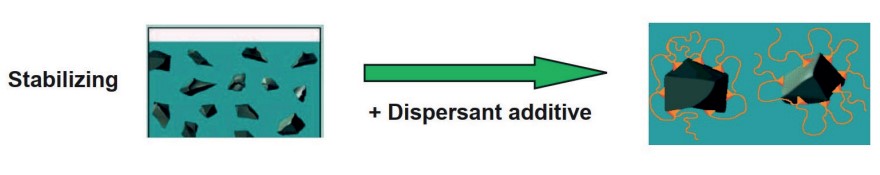

When dispersing pigments, in particular organic pigments, one often encounters problems such as flocculation, insufficient colour or transparency, poor rheological behaviour or bad stability. These issues arise along every step of the coatings life cycle from production and storage through to the end-use performance of the film. The dispersing of solid pigments or fillers into the liquid phase of binder solutions is an important step in paint and coatings production influencing optical properties like gloss and colour strength. Dispersion control additives are used to improve and accelerate the dispersion process and to stabilize the dispersion during storage.

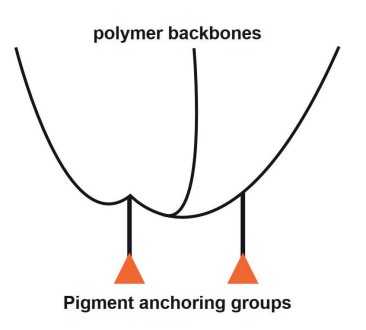

They are built of linear or branched polyacrylate or polyurethane structures with a molecular weight between 5,000 g/mol - 30,000 g/mol and have special groups which have high affinity towards specific sites on the pigment surface. These are called anchoring groups, and are built in at strategic points on the polymer backbone.

Anchoring groups enable strong interaction between the dispersion control additive and the pigment surface. This interaction is much stronger compared to the anchoring mechanism of the conventional low molecular weight types. Because these dispersion control additives have multiple adsorptions points, they are therefore connected to numerous sites on the surface of the pigment particles. The remaining parts of the dispersion control additive act as a steric barrier to the surroundings by stretching into the liquid phase and assuring an effective steric hindrance preventing flocculation.

| Description / Application | Active content | % | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OMNIVADD 4000 - HIGH MOLECULAR WEIGHT DISPERSANTS BASED ON BLOCK COPOLYMER | ||||||||||||

|

Omnivadd EP 4029 |

VOC- and solvent-free high molecular weight wetting and dispersing additive | 10 | 30-50 | 25-30 | 100 | • | • | • | ||||

|

Omnivadd WP 4276* |

Particularly recommended for carbon black pigments. Ideal for pigment concentrates for polyols and PVC plastisols and color masterbatches for thermoplastics | - | - | - | 100 | • | ||||||

|

Omnivadd WP 4519 |

Aqueous coating systems, printing inks and adhesives. Ideal for resin-free pigment concentrates | 8-12 | 30-50 | 50-60 | 40 | • | ||||||

| OMNIVADD 4000 - HIGH MOLECULAR WEIGHT DISPERSANTS BASED ON POLYURETHANE CHEMISTRY | ||||||||||||

|

Omnivadd- SP 4009 |

General-use industrial coatings where cost effective performance is vital | 10 | 30-50 | 15-25 | 60 | • | ||||||

|

Omnivadd XP 4010 |

General-use industrial coatings including coil coatings and decorative finishes | 5-10 | 20-40 | 25-30 | 50 | • | ||||||

|

Omnivadd XP 4046 |

General-use industrial coatings | 10 | 30-50 | 15-25 | 40 | • | ||||||

|

Omnivadd XP 4047 |

High quality industrial finishes including automotive OEM and refinish | 10 | 30-50 | 15-25 | 35 | • | • | |||||

|

Omnivadd SP 4061 |

Particularly suited for stabilizing carbon blacks with a fine particle size as well as organic pigments | 10 | 30-50 | 15-25 | 30 | • | ||||||

|

Omnivadd SP 4063 |

Solvent-based coatings, including automotive topcoats and high-quality industrial coatings. Ideal for pigment concentrates for high-end applications requiring durability | 10 | 25-50 | 20-30 | 45 | • | ||||||

|

Omnivadd XP 4100 |

High quality industrial finishes including automotive OEM, refinish, as well as universal solvent-based colorants | 10 | 30-50 | 15-25 | 50 | • | ||||||

The dispersing of solid pigments or fillers into the liquid phase of binder solutions is an important step in paint and coatings production influencing optical properties like gloss and colour strength. Dispersion control additives are used to improve and accelerate the dispersion process and to stabilize the dispersion during storage

They are built of linear or branched polyacrylate or polyurethane structures with a molecular weight between 5,000 g/mol - 30,000 g/mol and have special groups which have high affinity towards specific sites on the pigment surface. These are called anchoring groups, and are built in at strategic points on the polymer backbone.

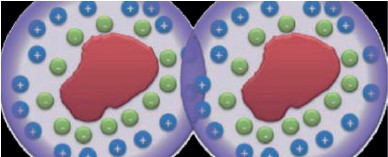

They are categorized according to their chemical structure and the nature of their hydrophilic groups (amphoteric, cationic, … etc). The molecular weight is between 800 and approximately 2000 g/mol which is too low to give enough steric hindrance for stabilization of organic and carbon black pigments.

The interaction of their polar groups with the pigment surface and the behaviour of the nonpolar chains in the medium determine their effectiveness.

The polar heads will form hydrogen bonding interactions between different pigment units resulting in a network that enhances the separation of the particles (controlled flocculation). Inorganic pigments are usually metal oxides which contain positive metal ions and negative oxide ions. These ions are good anchoring points on which the anchoring groups of the dispersion control additive can attach to (polar interactions).

| Description / Application | Active content | % | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OMNIVADD 5000 - RANGE LOW MOLECULAR WEIGHT DISPERSANTS | ||||||||||||

|

Omnivadd SP 5001 |

Cost effective dispersant based on fatty acids for primers and under-coats | 0.5-2.0 | - | 30-50 | 30 | • | • | |||||

|

Omnivadd SP 5005 |

Solvent borne industrial and marine coatings filled SMC & BMC | 0.2-2.0 | 2.0-5.0 | - | 52 | • | ||||||

|

Omnivadd SP 5010 |

All types of industrial coatings, composites, especially for inorganic pigments | 1.0-10.0 | - | - | 50 | • | ||||||

|

Omnivadd SP 5044 |

Solvent borne or solvent-free coating systems. Also for composites,SMC,BMC & bentonite gels | 0.2-2.0 | 2.0-5.0 | 30-50 | 52 | • | ||||||

|

Omnivadd XP 5054 |

Non-polar to medium-polar coating systems. Also for bentonite gels | 0.2-2.0 | 2.0-5.0 | 30-50 | 52 | • | ||||||

|

Omnivadd XP 5065 |

Polyurethane systems and stoving enamels. Also for orientation of aluminium pigments | 0.5-2.5 | - | - | 52 | • | ||||||

|

Omnivadd XP 5066 |

Polyurethane systems and stoving enamels. Strong anti-settling effect | 0.5-2.5 | - | - | 52 | • | ||||||

|

PureVadd 5510 |

Water and solvent borne systems. Strong anti-settling effects. Bio-based Content (ASTM D6866-21) : 53 % | 0.5-2.0 | 2.5-5.0 | - | 52 | • | • | |||||

|

Omnivadd SP 5107 |

Recommended for architectural coatings to stabilize titanium dioxide, fillers and other organic and in organic pigments | 3-5 | 5-8 | 8-10 | 90 | • | ||||||

|

Omnivadd SP 5135 |

Improve the wetting of pigment surfaces and organically treated Bentonites | 0.25-1.0 | - | 15.0-25.0 | 100 | • | • | |||||

|

Omnivadd XP 5165 |

Similar to Omnivadd XP 5065, but with different solvents combination | 0.5-2.5 | - | - | 52 | • | ||||||

|

Omnivadd SP 5207 |

Solvent borne architectural and decorative paints | 0.5-5.0 | 2.0-5.0 | - | 100 | • | • | |||||

|

Omnivadd SP 5217 |

Solvent borne, solventless coatings and printing inks. Excellent for Titanium Dioxide and extenders | 0.5-5.0 | - | - | 100 | • | • | |||||

|

Omnivadd SP 5244 |

Solvent-free version of Omnivadd SP 5044 | 0.1-1.0 | 1.0-2.5 | 15-25 | 100 | • | • | |||||

|

PureVadd 5266 |

Prevent flooding and floating and hard sedimentation. Bio-based Content(ASTM D6866-21) : 84 % | 0.25-1.25 | - | - | 100 | • | • | |||||

|

Omnivadd XP 5844 |

Solvent borne or solvent-free coating systems. Ideal for dispersing extenders in thermosetting resins | 0.1-1.5 | 1.0-3.0 | 20-30 | 80 | • | ||||||

Hybrid dispersant are modern low molecular weight dispersants. They contain anchoring mechanisms similar as in high molecular weight dispersants but have significant lower molecular weights varying between 1000 – 5000 g/mol. Due to the anchoring groups, multi adsorption is possible and therefore anchoring on organic- & carbon black pigments can be achieved. Compared to conventional low molecular weight dispersants the molecular weight of these hybrid dispersants are usually much higher which ensures more improved steric hindrance.

The active substance of hybrid dispersant is typically 100%. Because high molecular weight dispersants are usually having 30 – 60% activity, hybrid dispersants are very cost effective to use.

Unlike conventional low molecular weight dispersants, hybrid dispersants can be used for inorganic-, organic- and carbon black pigments.

| Description / Application | Active content | % | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OMNIVADD 6000 - RANGE MODERN LOW MOLECULAR WEIGHT DISPERSANTS | ||||||||||||

|

Omnivadd WP 6140 |

Solution of an ammonium salt of an acrylic polymer in water | 0.5-2.0 | - | - | 44 | • | ||||||

|

Omnivadd WP 6141 |

Especially suited for the dispersion of inorganic pigments. | 0.5-2.0 | - | - | 44 | • | ||||||

|

Omnivadd XP 6211 |

Acidic polyether, dispersant for solventbased and solvent-free coatings and composite, is particularly suitable for car putties | 0.5-2.0 | - | - | 100 | • | ||||||

|

Omnivadd XP 6212 |

Acidic polyether, dispersant for solventbased and solvent-free coatings and composite | 5-10 | - | - | 100 | • | • | |||||

|

Omnivadd XP 6215 |

Anionic wetting agent to improve compatibility and color acceptance of all kinds of tinting pastes in both solvent and water-based systems VOC-Free | 3-10 | 10-20 | 15-25 | 100 | • | • | |||||

|

PureVadd 6220 |

Hybrid dispersant to improve compatibility and color acceptance of universal colorants in base paints. Bio-based Content (ASTM D6866-21) : 55 % | 5-10 | 10-20 | 15-25 | 100 | • | • | |||||

|

PureVadd 6225 |

Hybrid dispersant for universal colorants for tinting systems. Bio-based Content (ASTM D6866-21) :29 % | 5-10 | 10-20 | 15-25 | 100 | • | • | |||||

|

PureVadd 6228 |

Hybrid dispersant for oil and solventbased systems and colorants. Also for heatset and offset inks. Bio-based Content (ASTM D6866-21) :55 % | 5-10 | 10-20 | - | 100 | • | ||||||

|

Omnivadd XP 6230 |

Aliphatic polyether with acidic groups | 1-3 | - | - | 100 | • | • | • | ||||

|

Omnivadd XP 6231 |

Aliphatic polyether with acidic groups especially for PVC plastisol purposes | 1-3 | - | - | 100 | • | • | • | ||||

|

PureVadd 6245 |

Hybrid dispersant for universal colorants for tinting systems, VOC- free and low viscosity pumpable dispersant. Bio-based Content (ASTM D6866-21) :29 % | 5-10 | 10-20 | 15-25 | 100 | • | • | • | ||||

|

Omnivadd XP 6525 |

Hybrid dispersant stabilizing all kind of pigment and extenders in waterborne coatings, especially in decorative coatings | 10-20 | 20-40 | - | 50 | • | ||||||

|

Omnivadd XP 6540 |

Triple tail technology dispersant to improve stability of tinting pastes as well as dispersant for organic, inorganic and pearlescent pigments | 0.5-2.0 | 2.5-5.0 | - | 62 | • | ||||||

| Description / Application | Dosage| % | Active Content | % | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| OMNIVADD 7000 - RANGE MISCELLANEOUS | |||||||||||

|

Omnivadd SP 7023 |

Highly effective rheological control additive. For water-based adhesives or latex. Especially suited for adhesive systems | 0.5-3.0 | 55 | • | |||||||

|

Omnivadd VA 7500 |

Increased pigment loading in the mill-base or pigment concentrate | 1.0-3.0 | 100 | • | • | ||||||

|

Omnivadd VA N100 |

Derivative of a family of highly effective, low viscosity dispersing agent for water-borne coating systems | 0.5-2.0 | 90 | • | • | ||||||