Although the coating might be for different purposes; protective, decorative or both, it is the eye-catcher for its users and consumers. It is exposed to “the world” and has not only to withstand some severe circumstances like weathering, but is responsible for the appearance of the coating, colour, brightness, gloss and the “touch”. It all starts at the surface. In most cases, superior surface properties cannot be achieved without the addition of slip & levelling additives which alter the surface properties of the coating.

Polysiloxanes have a very high surface activity and therefore are often used as surface control additives. Silicone-based surface control additives are modified by polyethers, polyesters or alkyl side groups to improve recoatability and inter-coat adhesion. Modification parameters are silicone content, molecular weight, and modification degree.

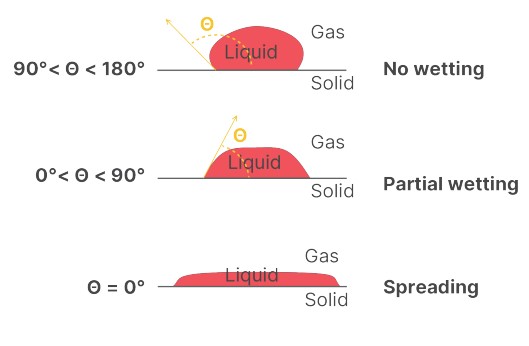

Polyacrylates, homo- and copolymers based on (meth)acrylic monomers are well known surface control additives. In addition to their positive impact on flow and levelling, acrylic homoand co-polymers are effective as air-release agents. Since they are not reducing the surface tension of the coating to the extent of silicone-based products, the wetting of substrate surfaces is improved (substrate wetting).

| Description / Application | Incorporation | Dosage | % * | Active content| % | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OMNIVADD 3000 - SILICONE-CONTAINING SLIP & LEVELLING ADDITIVES | |||||||||||||

|

Omnivadd XF 3030 |

Improve slip and mar resistance, very compatible | Any stage | 0.1-1.0 | 52 | • | • | |||||||

|

Omnivadd XT 3031 |

Good substrate wetting of critical substrates, heat resistant silicone additive, slip,mar resistance | Any stage | 0.1-1.0 | 52 | • | • | |||||||

|

Omnivadd XF 3033 |

Improve surface flow, excellent compatibility in clear coat wetting & anticratering | Any stage | 0.1-1.0 | 15 | • | ||||||||

|

Omnivadd EF 3077 |

Unique wetting and spreading properties and can also improve flow and levelling properties | End of process | 0.1-1.0 | - | • | • | • | ||||||

|

Omnivadd XF 3230 |

100% version of Omnivadd XF 3030 | Any stage | 0.05-0.5 | 100 | • | • | • | ||||||

|

Omnivadd XF 3236 |

Solvent borne wood finishes, industrial coatings and solvents-free coatings | After thinning | 0.02-0.3 | 100 | • | • | |||||||

|

Omnivadd XF 3290 |

Premium additive that increases slip, surface smoothness and “soft-touch” effect | Any stage | 0.05-0.5 | 100 | • | • | • | ||||||

|

Omnivadd WF 3580 |

Anti-cratering and leveling agent for waterborne coatings | After or prior to processing | 0.1-1.0 | 100 | • | ||||||||

|

Omnivadd WF 3581 |

Leveling agent for waterborne coatings with impregnating properties | Any stage | 0.2-1.0 | 100 | • | ||||||||

|

Omnivadd WF 3585 |

Solution of Omnivadd WF 3580 | After or prior to processing | 0.2-2.0 | 52 | • | ||||||||

| Description / Application | Incorporation | Dosage | % * | Active content| % | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OMNIVADD 3000 - SILICONE-FREE SLIP & LEVELLING ADDITIVES | |||||||||||||

|

Omnivadd WD 3052 |

Emulsifier in coatings, printing inks, adhesives and detergents | End of process | 0.05-1.0 | 50 | • | ||||||||

|

Omnivadd SF 3058 |

Anti-cratering and leveling additive, enhances shine and long wave effect for recoatability and interlayer adhesion | Any stage | 0.1-1.0 | 52 | • | • | |||||||

|

Omnivadd WF 3070 |

Emulsifier in coatings, printing inks, adhesives and detergents | End of process | 0.05-1.0 | 30 | • | ||||||||

|

Omnivadd EF 3088 |

Provides ‘long wave’ levelling performance and increases gloss of the coating system | End of process | 0.4-2.0 | 50 | • | ||||||||

|

Omnivadd XF 3257 |

Good slip, gloss enhancement, pigment treatment and leveling | Prior to processing | 0.01-0.5 | 100 | • | • | • | ||||||

|

Omnivadd XF 3260 |

Wetting, levelling and flow control agent with excellent anti-cratering properties | End of process | 0.05-1.0 | 100 | • | • | |||||||

|

Omnivadd XF 3261 |

Enhances the leveling of coatings. Prevents shrinkage, ensuring superior finish and performance | Any stage | 0.05-0.5 | 100 | • | • | |||||||

|

Omnivadd XF 3541 |

Increases coating spreading ability, wetting & leveling performance. Offers excellent anti-shrinkage properties | Any stage | 0.1-1.0 | 100 | • | ||||||||

|

Omnivadd XF 3549 |

Reduces surface tension. Enhances coating spreading. Good anti-shrinkage performance | Any stage | 0.1-1.0 | 100 | • | ||||||||

|

Omnivadd XF 3572 |

Anionic substrate wetting agent | End of process | 0.1-0.5 | 70 | • | ||||||||

|

Omnivadd WF 3575 |

Excellent substrate wetting, levelling and anti-cratering | After or prior to processing | 0.5-1.5 | 55 | • | ||||||||

|

Omnivadd XF 3577 |

Reduces surface tension. Increases coating spreading, adhesion and substrate wettability | Any stage | 0.1-1.0 | 100 | • | ||||||||

|

Omnivadd XF 3772 |

Solvent borne or solvent free systems, coil coatings, OEM and industrial coatings | End of process | 0.5-2.0 | 60 | • | • | • | ||||||

|

Omnivadd SF 3777 |

Strong anti-cratering | End of process | 0.5-1.0 | 70 | • | • | |||||||

|

Omnivadd VA 3906 |

Polyethylene wax for anti-blocking and scratch resistance | Depending on system | 0.5-2.0 | 100 | • | • | |||||||